Services

Toolmaking in China

and change management in Europe

Many years of experience in the field of tool and process engineering guarantee an efficient and timely completion of your project.

By using the most modern CAD programs and CNC machining centers, we can meet the requirements Ensure accuracy for excellent quality for you.

2K series tools

with transfer technology or with a Coindex plate

QR code

Measurement release electrodes

Electrodes

stored in the holder

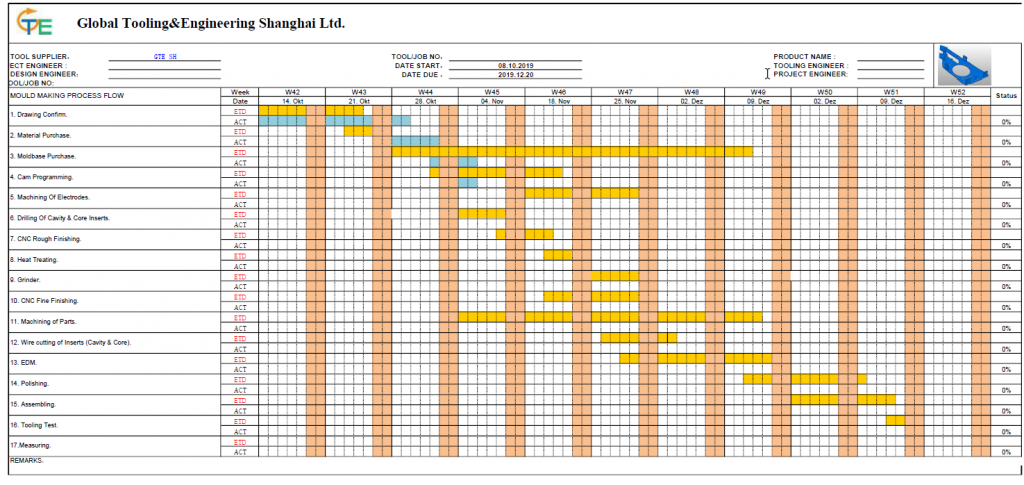

Status reports and data

Weekly status report

Interfaces 3D (Step, IGS, UG)

Data transfer FTP server

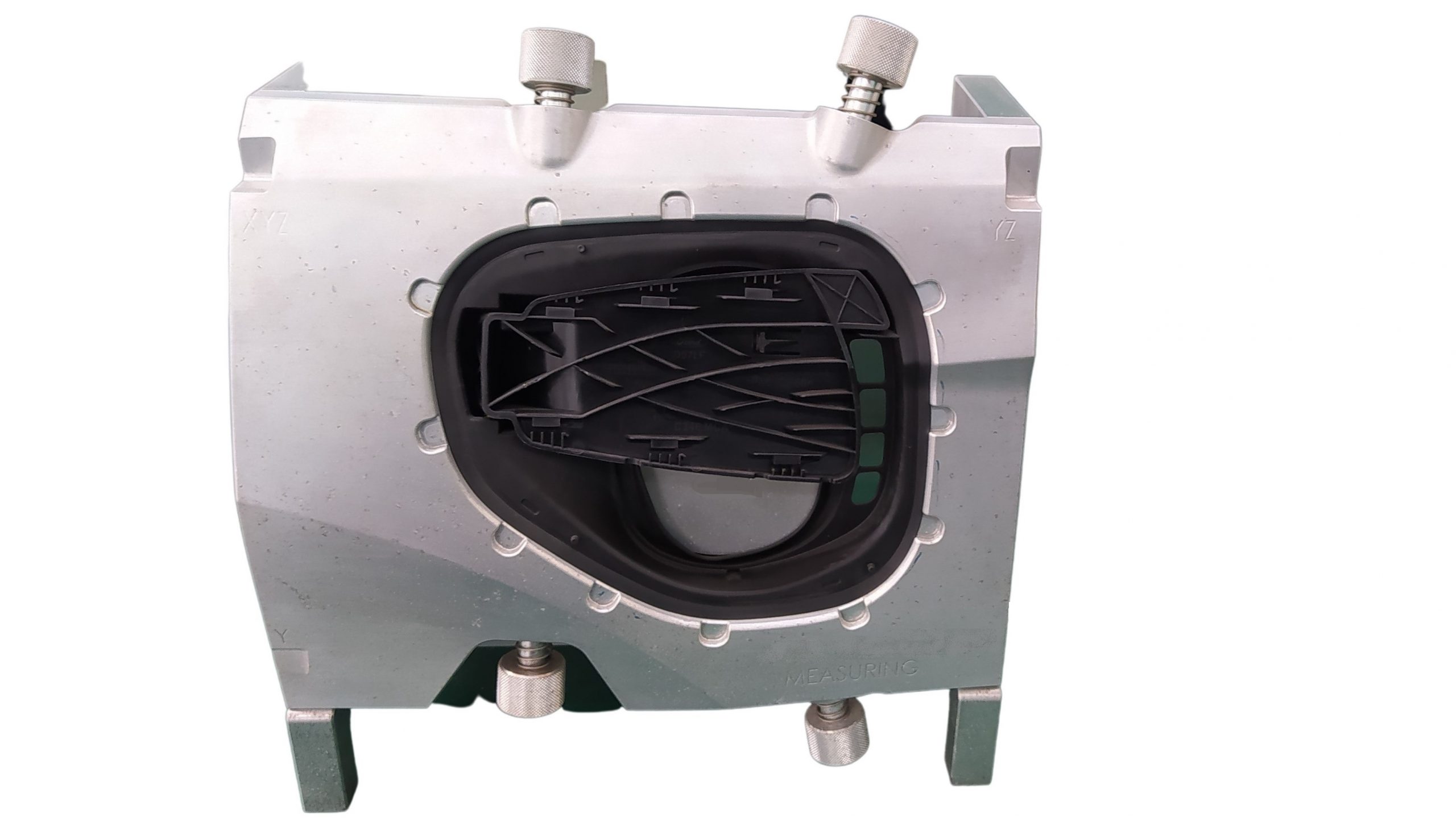

2 + 2 series tools

Development of single or multiple designed forms

Cubings, test plates, removal hand

Production of gauges/cubings of all kinds.

Production in close coordination with customers

Inspection of the required quality features

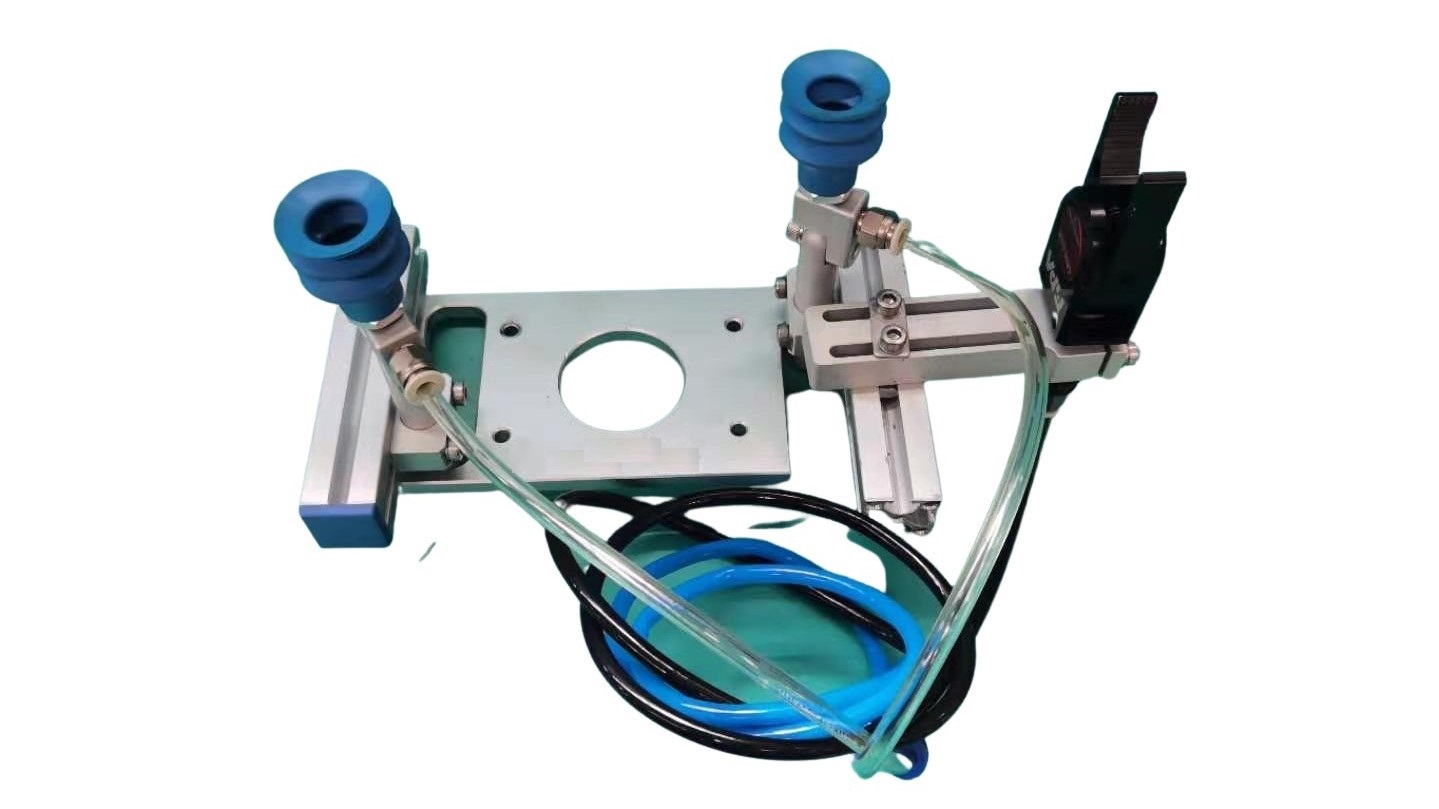

Development and production of suitable removal grippers

Flexible Round

Standard X-profile technology

Plate technology

Project flow at gte in china

- Customer’s request

- The offer is made within 5 working days, including freight and customs clearance

- After the nomination and the final design, the customer receives a DFM report after 7 days, which verifies the tool design and article design

- After agreeing the DFM report with the customer, the final construction of the mold begins

- In approx. 8-12 working days, the customer receives his tool design, which has to be officially approved

- A weekly progress report is sent to the customer, which is visually backed up with pictures

- After the construction period, which is usually 6-8 weeks (depending on the article design), the first parts are produced in-house and

then sent to the customer after final testing - If the part or the mold has been accepted by the customer and all criteria are met, the mold can be shipped to Europe by ship, train or plane

our partner for repair service in Europe